Our Product

W metal beam

Crash Barrier

W metal beam crash barrier

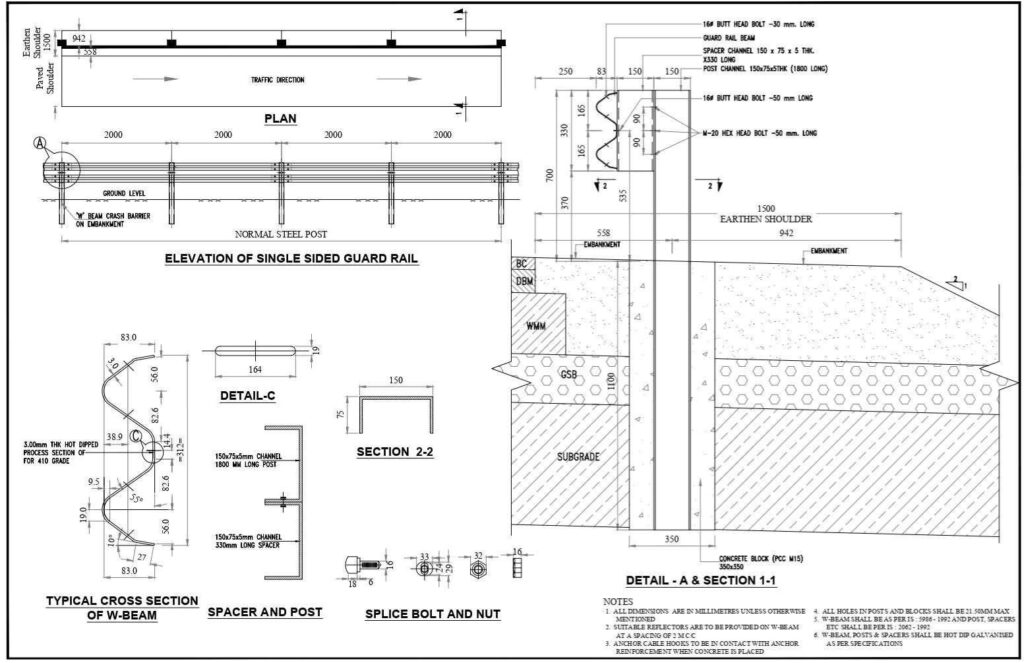

W Beam crash barriers are a type of roadside safety barrier designed to prevent vehicles from veering off the road and causing accidents. Named for their distinct “W” shape, these barriers are made from high-strength steel and are typically used along highways, roadways, and other high-traffic areas. Their primary function is to absorb and dissipate the energy from a collision, effectively redirecting vehicles and minimising the risk of severe accidents. The design ensures that upon impact, the barrier deforms in a controlled manner to cushion the collision, making it a critical component in road safety infrastructure.

W Beam crash barriers play a crucial role in enhancing road safety across various environments. They are commonly installed along highways, urban roads, and industrial sites to protect against vehicle accidents. These barriers are essential in preventing vehicles from crossing into opposing lanes, off the road, or into hazardous areas. Their effectiveness in reducing the severity of accidents and protecting both motorists and pedestrians makes them indispensable in modern infrastructure projects. Key features of W Beam crash barriers include durability, impact resistance, and compliance with international safety standards, ensuring they meet the highest levels of performance and reliability.

144000 MT

Cumulative Crash Barrier Production Capacity

5000 + MT

Ready Stock

H2

Containment Level

Specification

Product Specification

Explore the precise W Beam crash barrier specifications, featuring high-strength steel, rigorous standards compliance, and proven impact resistance.

- On-ground safety barrier

- Conformity with Class H1W3, H1W4, H1W5

- 2.8mm cold-rolled thickness

Our W beam crash barriers have been designed in adherence to road safety regulations and the latest traffic infrastructure. The advantages of our products include:

- Complete Range of W Beam Metal Crash Barriers Discover our extensive range of W Beam metal crash barriers, designed to meet diverse safety needs on roads and highways. Each barrier is engineered for maximum impact resistance.

- Premium-Grade Raw Materials Our W Beam crash barriers are crafted from premium-grade steel sourced from industry leaders. This ensures superior quality and reliability, making our barriers highly durable and effective.

Manufactured in adherence to global standards, our high-precision W Beam crash barriers offer exceptional safety and durability. As a leading W Beam barrier manufacturer in India, we ensure superior quality and performance.

- Engineered Excellence for Best Quality Our W Beam metal crash barriers are engineered to the highest standards, ensuring premium quality and reliability. Each barrier is crafted to deliver superior performance and safety.

- Made from Meticulously Sourced Premium Raw Materials Utilising top-grade materials from renowned suppliers, our W Beam crash barriers guarantee durability and strength. This meticulous sourcing ensures long-lasting protection and high-performance standards.

Manufacturing

Manufacturing Process

Our W beam crash barriers are manufactured in a systematic and carefully monitored process and adhering to w beam crash barrier specifications, guaranteeing durability, safety, and precision.