Our Product

EN-1317

Crash Tested Barrier

EN-1317 Crash Tested Barrier

Crash barriers are vital safety installations designed to prevent vehicles from veering off the road or colliding with hazardous objects. They serve as a critical component in road safety, reducing the severity of accidents and protecting both occupants and pedestrians. By absorbing and redirecting the impact energy, crash barriers help to mitigate the consequences of collisions, making roads safer for everyone.

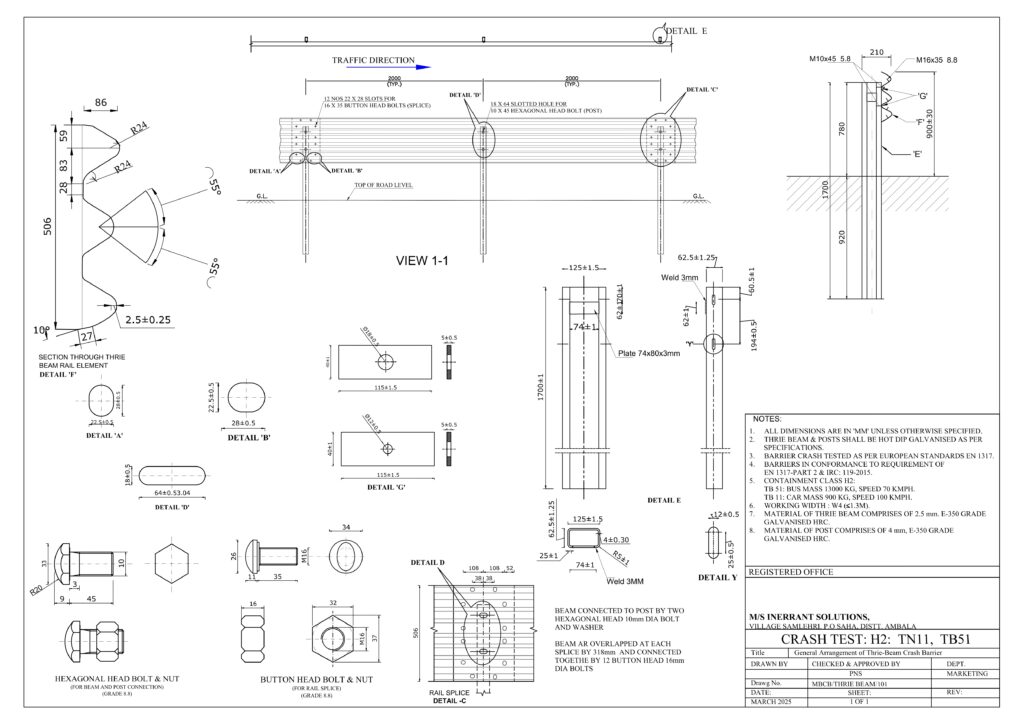

Among the various types of crash barriers, the W Beam crash barrier is one of the most common and effective. The W Beam crash barrier, named for its distinctive ‘W’ shape, is constructed from metal and is known for its durability and resistance to impact forces. These barriers work by deforming upon impact, which absorbs and dissipates energy, thereby reducing the force of the collision and guiding the vehicle back onto the road. The design of the W Beam barrier allows it to effectively handle a range of impact scenarios, making it a preferred choice for highways, roads, and other high-traffic areas.

144000 MT

Cumulative Crash Barrier Production Capacity

5000 + MT

Ready Stock

H1

Containment Level

Specification

Product Specification

Discover the advanced technical specifications of Inerrant Solutions crash barriers, including W-Beam, Thrie Beam, and Pedestrian Guard Rails, engineered for superior durability, impact resistance, and compliance with global safety standards.

- Material Quality: Crafted from premium-grade galvanised steel sourced from trusted suppliers like TATA and SAIL, ensuring durability, corrosion resistance, and reliability for long-term performance.

- Design Compliance: Inerrant Solutions crash barriers adhere to EN 1317 and IRC 119 standards, guaranteeing exceptional safety and effectiveness for diverse road and industrial applications.

- Load Bearing Capacity: Our W-Beam and Thrie Beam barriers are engineered to withstand high-impact forces, ensuring optimal containment and redirection of vehicles upon collision.

Explore the key features of Inerrant Solutions crash barriers, designed for superior impact resistance, durability, and compliance with global standards, making us a trusted crash barrier manufacturer in India.

- Impact Resistance: Inerrant Solutions crash barriers are engineered for high impact resistance, ensuring maximum safety and protection in collision scenarios.

- Global Standards: Our barriers comply with EN 1317 and IRC 119, solidifying our position as a top crash barrier manufacturer in India.

Here’s a roundup of the unmatched advantages of Inerrant Solutions crash barriers, combining superior durability, safety compliance, and innovative engineering, making us a leading crash barrier manufacturer and supplier in India.

- Unmatched Durability: Built with premium-grade galvanised steel, our crash barriers ensure long-lasting performance, making us a trusted crash barrier manufacturer in India.

- Enhanced Road Safety: Engineered to absorb impact effectively, our barriers reduce accident risks, providing superior safety on highways, bridges, and urban road networks.

Manufacturing

Manufacturing Process

Our thrie beam Metal Beam Crash Barriers are manufactured in a systematic and carefully monitored process, guaranteeing durability, safety, and precision.